Products

Telephone:

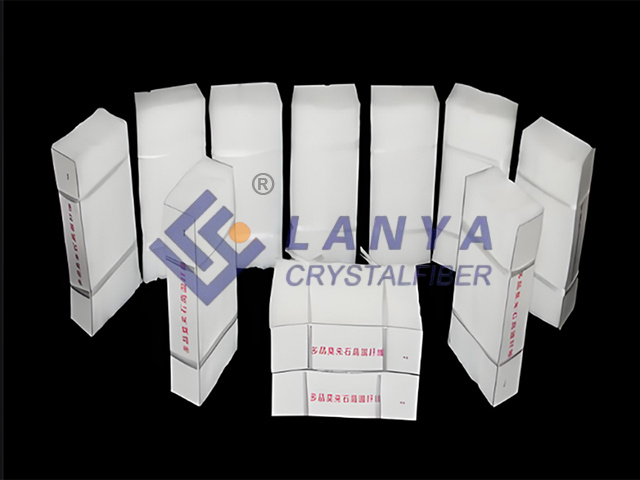

Polycrystalline mullite Fiber veneer block

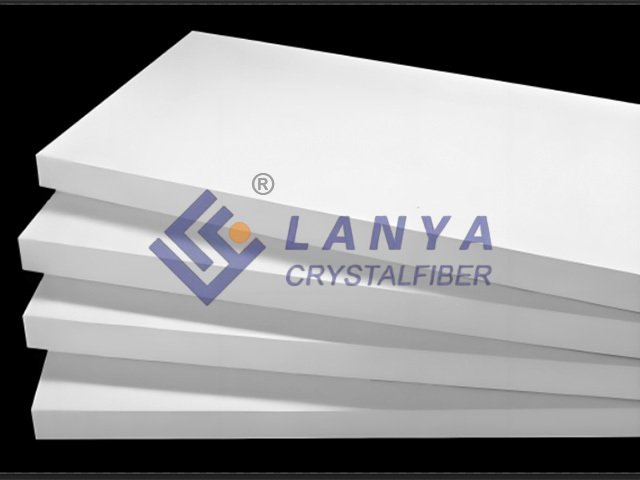

Polycrystalline mullite fiber veneer block is formed by cutting and compressing polycrystalline mullite fiber through special process. Does not contain any binder or other ingredients, has excellent elasticity and flexibility, the highest use temperature can reach 1600 ℃. They in the oxidizing atmosphere, neutral atmosphere or partial reduction atmosphere under the long-term withstand this temperature, can still maintain its original toughness, strength, softness and fiber structure, do not contain slag ball, can be used by a variety of high-temperature industrial furnace hot surface lining paste, has a particularly obvious thermal insulation performance, is the crystallization of high-tech industrialization.

Classification:

Products

Key words:

Polycrystalline mullite Fiber veneer block

E-mail:dqlanya@163.com

Product Description

1. product description:

Polycrystalline mullite fiber veneer block is formed by cutting and compressing polycrystalline mullite fiber through special process. Does not contain any binder or other ingredients, has excellent elasticity and flexibility, the highest use temperature can reach 1600 ℃. They in the oxidizing atmosphere, neutral atmosphere or partial reduction atmosphere under the long-term withstand this temperature, can still maintain its original toughness, strength, softness and fiber structure, do not contain slag ball, can be used by a variety of high-temperature industrial furnace hot surface lining paste, has a particularly obvious thermal insulation performance, is the crystallization of high-tech industrialization.

2. product features:

Low heat storage, low thermal conductivity, thermal shock resistance, good sound absorption performance, high heat reflection performance, uniform fiber diameter, excellent chemical stability, resistance to airflow erosion

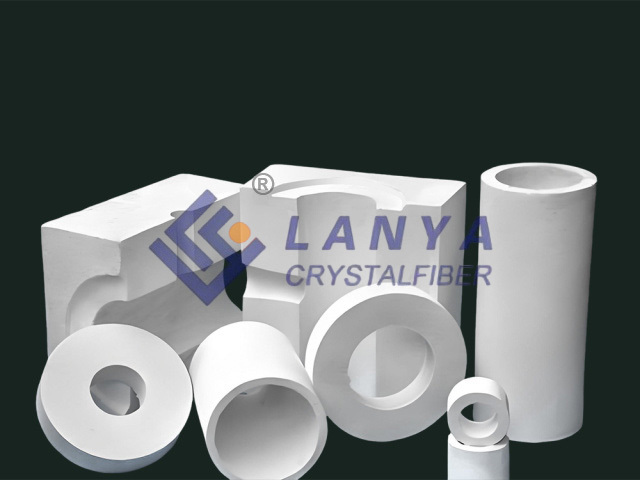

3. product applications:

Heating furnace, heat treatment furnace, shuttle kiln, tunnel kiln, roller kiln, furnace door, furnace cover closurephysical and chemical indicators of

4. products:

| Name/Item | Classification temperature ℃ | Al203 | SIO2 | Bulk weight kg/m³ | coefficient of thermal conductivity (W/m.k) |

Reburn line contraction | Fiber diameter | specific heat | Melting point ℃ |

| LY-1600 veneer block | 1600 | 72-75% | 25-28% | 100 | 1000-0.226 1200-0.295 1300-0.337 1400-0.387 |

1500x6H<1% | 3-5 | 1024kj/kg.k | 1840 |

| LY-1700 veneer block | 1700 | 80% | 20% | 100 | 1000-0.226 1200-0.295 1300-0.337 1400-0.387 |

1600x6H<1%6 | 3-5 | 1024kj/kg.k | 1840 |

Note: The technical data of the product is the average value obtained from the adopted test standards and will fluctuate within a certain range. This data does not represent the quality assurance data of the product.

Previous Page

Next

Previous Page

Next Page

Related Products

Message

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.