Products

Telephone:

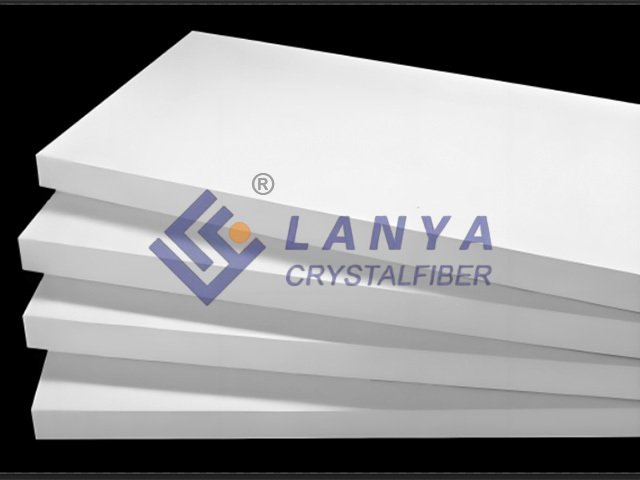

Fiberboard

The fiberboard is formed by wet vacuum suction filtration and pressure with loose cotton and inorganic adhesive, and is calcined at high temperature according to different models. The product has excellent characteristics of low bulk density and high strength at the same time. It is a multi-purpose product and can be applied to the direct impact of flame resistance and high temperature airflow on the hot surface of furnace lining.

Classification:

Products

Key words:

Fiberboard

E-mail:dqlanya@163.com

Product Description

1. product description:

The fiberboard is formed by wet vacuum suction filtration and pressure with loose cotton and inorganic adhesive, and is calcined at high temperature according to different models. The product has excellent characteristics of low bulk density and high strength at the same time. It is a multi-purpose product and can be applied to the direct impact of flame resistance and high temperature airflow on the hot surface of furnace lining.

2. product features:

High temperature stability, low thermal conductivity, low heat capacity, thermal shock resistance, erosion resistance, easy processing and cutting performance, accurate thickness and size, good resistance to flame and airflow erosion, easy installation and use

3. product applications:

It can be used in areas that require toughness, self-bearing and heat insulation at the same time, and it has good resistance to mechanical damage. The fields include: pusher kiln, ladle furnace, bell kiln, tunnel kiln, roller kiln, aluminum melting furnace, heat treatment furnace and other insulation lining and backing.

4. products:

| Model | LY-1260 | LY-1400 | LY-1500 | LY-1600 | LY-1700 | LY-1800 | LY-1900 |

| Classification temperature (℃) | 1260 | 1400 | 1500 | 1600 | 1700 | 1800 | 1900 |

| Bulk weight (kg/m³) | 300-600 | 300-600 | 300-600 | 300-600 | 300-600 | 300-600 | 500-700 |

| Reburning line shrinkage (%) | (800 ℃ x 6h)<1 | (1200 ℃ x 6h)<1 | (1300 ℃ x 6h)<1 | (1500 ℃ x 6h)<1 | (1600 ℃ x 6h)≤ 1 | (1650 ℃ x 6h)≤ 1 | (1700 ℃ x 8h)≤ 1 |

| Chemical composition% | |||||||

| Al2O3 | 42 | 50 | 54 | 72 | 75 | 80 | 85 |

| Al2O3 SiO2 | 98 | 99 | 99 | 99 | 99.5 | 99.5 | 99.5 |

| Fe2O3 | 0.2 | 0.2 | - | - | - | - | - |

| ZrO2 | - | - | - | - | - | - | - |

Previous Page

Next

Previous Page

Next Page

Related Products

Message

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.