Products

Telephone:

Fiber Module

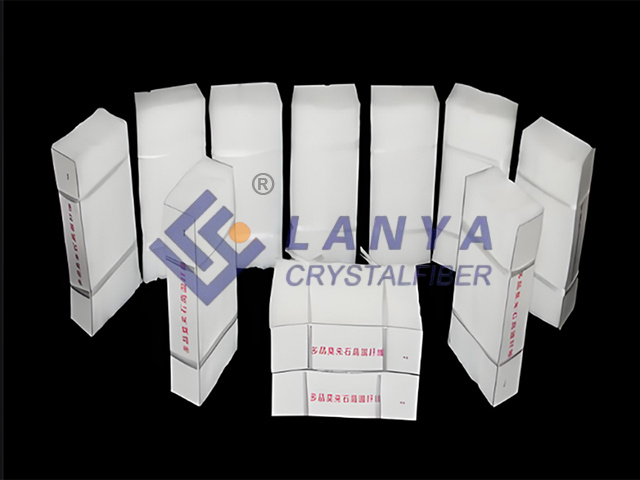

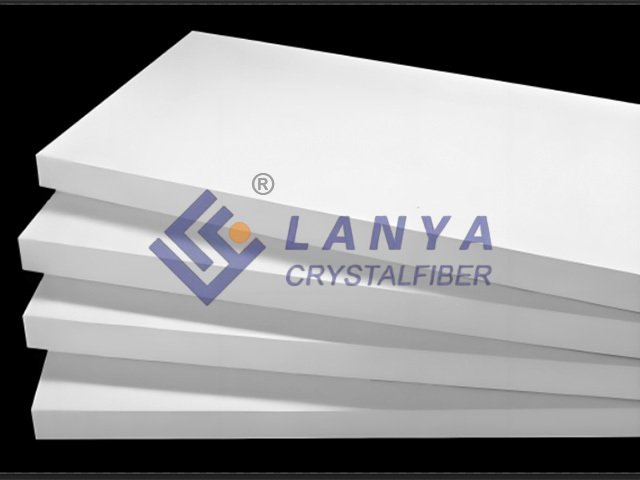

The fiber module is made of fiber needled blanket made of corresponding materials with excellent performance according to the structure and size of the fiber module and made by professional technicians and special processing equipment. In order to ensure that the modules are extruded to form a seamless and tight thermal insulation whole after the wall lining is completed, a certain compression amount is maintained during the manufacturing process, and a new refractory lining product is introduced in order to simplify and speed up the kiln construction and improve the integrity of the furnace lining. The size of the product is regular, can be directly fixed on the steel plate anchor nail of the industrial kiln shell, has good fire resistance and heat insulation effect, improves the integrity of the kiln fire resistance and heat insulation, and promotes the progress of the kiln masonry technology. The classification temperature of the product is 1000-1600 ℃. Users can adopt different fiber modules according to the kiln structure, and can also process and produce according to user requirements.

Classification:

Products

Key words:

Fiber Module

E-mail:dqlanya@163.com

Product Description

1. product description:

The fiber module is made of fiber needled blanket made of corresponding materials with excellent performance according to the structure and size of the fiber module and made by professional technicians and special processing equipment. In order to ensure that the modules are extruded to form a seamless and tight thermal insulation whole after the wall lining is completed, a certain compression amount is maintained during the manufacturing process, and a new refractory lining product is introduced in order to simplify and speed up the kiln construction and improve the integrity of the furnace lining. The size of the product is regular, can be directly fixed on the steel plate anchor nail of the industrial kiln shell, has good fire resistance and heat insulation effect, improves the integrity of the kiln fire resistance and heat insulation, and promotes the progress of the kiln masonry technology. The classification temperature of the product is 1000-1600 ℃. Users can adopt different fiber modules according to the kiln structure, and can also process and produce according to user requirements.

2. product features:

Excellent chemical stability; Excellent thermal stability; Excellent elasticity. The ceramic fiber module is in a pre-pressed state. After the furnace lining is built, the expansion of the ceramic fiber module makes the furnace lining seamless and can compensate the shrinkage of the fiber furnace lining to improve the thermal insulation performance of the fiber furnace lining. The overall performance is good. Excellent thermal stability and thermal shock resistance; The ceramic fiber module is installed quickly, and the anchor is set on the cold lining surface of the wall, can reduce the anchor material requirements.

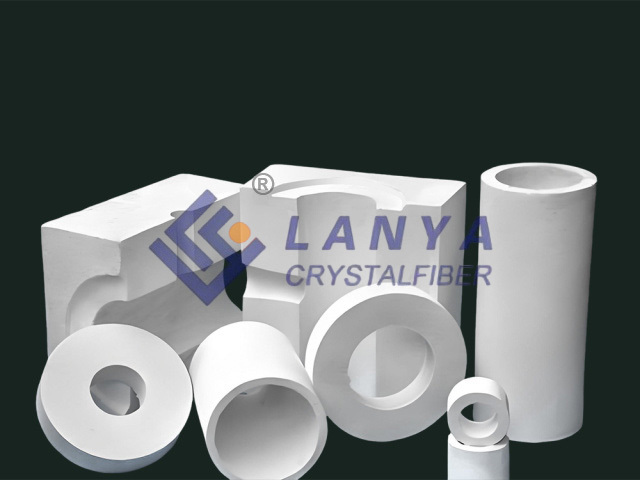

3. product applications:

Petrochemical industry furnace lining insulation; metallurgical industry furnace lining insulation; ceramic, glass and other building materials industry furnace lining insulation; heat treatment industry heat treatment furnace lining insulation; other industrial furnace lining.

4. products:

| Model | LY-1260 | LY-1350 | LY-1430 | LY-1600 |

| Classification temperature (℃) | 1260 | 1350 | 1430 | 1600 |

| Color | White | White | White | White |

| Bulk weight (kg/m³) | 160-260 | 160-260 | 160-260 | 160-260 |

| Material | ceramic fiber | polycrystalline mullite fiber | ||

| Chemical composition% | ||||

| Al2O3 SiO2 | 99 | 99 | 84 | 99.70 |

| ZrO2 | - | - | 15-17 | - |

| Gr | - | - | - | - |

| Fe2O3 | <0.2 | <0.2 | <0.2 | - |

Previous Page

Next

Previous Page

Next Page

Related Products

Message

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.