Products

Telephone:

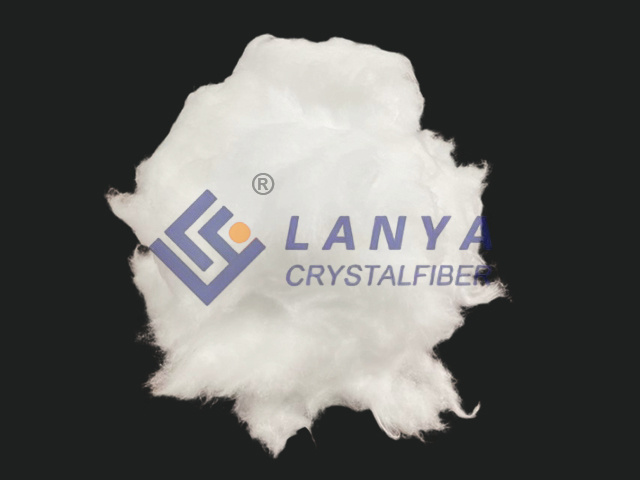

Polycrystalline mullite Fiber cotton

Alumina crystal fiber (polycrystalline mullite fiber is one of the class) with its ceramic fiber loose cotton using advanced spinning process production, its basic characteristics are stable performance under high temperature, light weight, low heat capacity, good thermal shock resistance, corrosion resistance and sound absorption performance. Modern high-tech can make lightweight refractory materials suitable for special requirements and meet customer needs.

Classification:

Products

Key words:

Polycrystalline mullite Fiber cotton

E-mail:dqlanya@163.com

Product Description

1、 Product Description:

Polycrystalline mullite fiber is a new type of ultra lightweight high-temperature refractory fiber both domestically and internationally. It is two different products in the entire Al2O3-SiO2 ceramic fiber system, with a usage temperature of 1500-1700 degrees, which is 200-400 degrees higher than that of glassy fibers. It can be widely used for lining insulation of high-temperature industrial kilns and other thermal equipment in metallurgy, machinery, electronics, ceramics, chemical industry, aerospace, etc. To achieve the goal of energy conservation, increased production, extended furnace life, and improved working environment. The appearance is white, smooth, soft, and elastic, especially like degreased cotton.

2、 Product features:

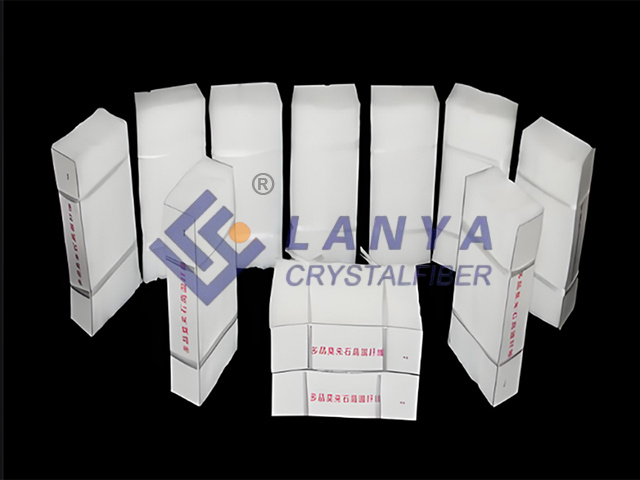

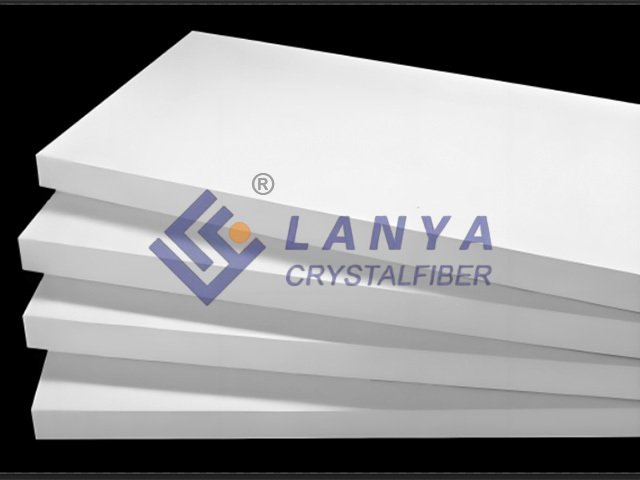

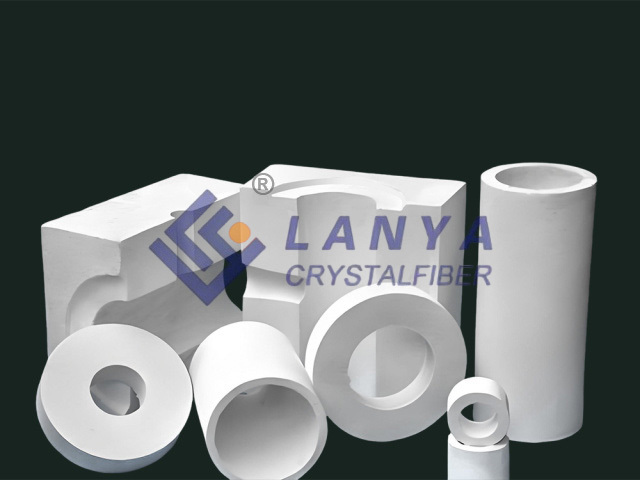

Polycrystalline mullite fiber is a unique type of polycrystalline refractory fiber that exists in the form of mullite crystal phase. The manufacturing process is complex and the technological content is high. Only a few developed countries can produce this product abroad, such as Silicon Carbide Company in the United States, ICI (ICI) Company in the United Kingdom, and several companies in Japan, Germany, etc. Polycrystalline mullite fibers and glassy fibers have completely different production processes. They are prepared using a chemical "colloid method" and are chemically formulated to form a single crystal mullite (Al2O3, SiO2). The chemical composition is AL2O3 72% and SiO2 28%. The principle is to make soluble aluminum and silicon into a colloidal solution with a certain viscosity, spin the liquid using conventional methods, and then complete the crystal phase transformation through high-temperature heat treatment to produce mullite fibers. The produced fiber cotton (in bulk) can be used as a filling material for high-temperature interlayer. By wet vacuum forming the bulk cotton, PMF fiber series varieties can be produced, such as boards, felt, bricks, standardized prefabricated parts, modules, composite components, etc.

Polycrystalline alumina fibers are crystalline fibers mainly in the form of corundum phase, which are also produced by chemical "colloid method". The manufacturing process is more complex, and the chemical composition is AL2O395%, SiO25%. The fiber cotton (loose) produced can be made into boards, bricks, standardized prefabricated parts, etc. by wet vacuum forming.

3、 Product application

Filling, sealing, and insulation in high-temperature environments (kiln cars, pipelines, kiln doors, etc.), fiber composite materials (such as friction plates, etc.), various industrial furnace linings (hot surfaces and backings), building fireproof, sound-absorbing, and high-temperature filtering materials, raw materials for deep processed products (refractory fiber paper, vacuum formed felt/board, or other products, etc.)

Previous Page

Previous Page

Related Products

Message

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.